Ana iya amfani da tsaftacewar Laser ba kawai don tsaftace gurɓataccen ƙwayar cuta ba, har ma da abubuwan da ba su da kyau, ciki har da lalata ƙarfe, ƙwayoyin ƙarfe, ƙura, da dai sauransu. Ga wasu aikace-aikace masu amfani.Waɗannan fasahohin sun balaga sosai kuma an yi amfani da su sosai.

1. Tsabtace tsafta:

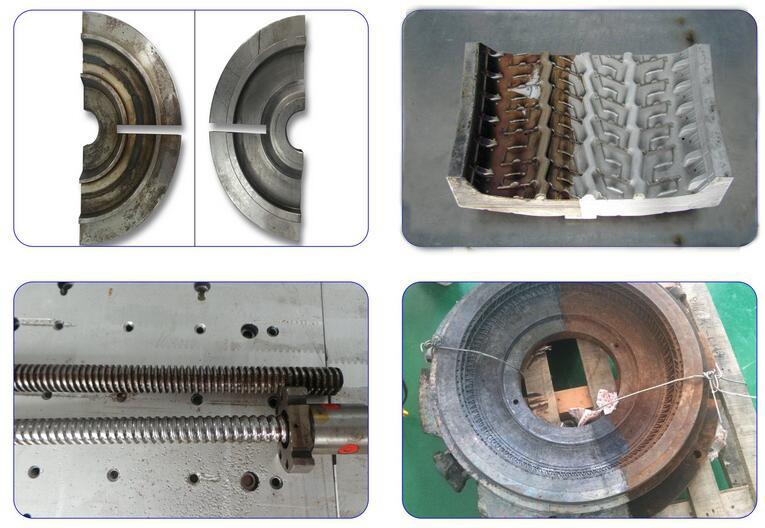

Kowace shekara, masu kera taya a duk faɗin duniya suna yin ɗaruruwan miliyoyin taya.Tsabtace kayan taya a lokacin aikin samarwa dole ne ya zama mai sauri da abin dogara don adana lokaci.Hanyoyin tsaftacewa na gargajiya sun haɗa da fashewar yashi, ultrasonic ko carbon dioxide tsaftacewa, da dai sauransu, amma waɗannan hanyoyin yawanci dole ne su kwantar da zafi mai zafi na tsawon sa'o'i da yawa, sa'an nan kuma motsa shi zuwa kayan tsaftacewa don tsaftacewa.Yana ɗaukar lokaci mai tsawo don tsaftacewa da sauƙi yana lalata daidaiton ƙirar., Magungunan sinadarai da hayaniya kuma na iya haifar da al'amurran tsaro da kare muhalli.Yin amfani da hanyar tsaftacewa na laser, saboda ana iya watsa laser ta hanyar fiber na gani, yana da sauƙi a amfani;saboda ana iya haɗa hanyar tsaftacewa ta laser zuwa fiber na gani, ana iya tsabtace jagorar haske zuwa kusurwar matattu na mold ko ɓangaren da ba shi da sauƙin cirewa, don haka ya dace don amfani;Babu iskar gas, don haka ba za a samar da iskar gas mai guba ba, wanda zai shafi amincin yanayin aiki.An yi amfani da fasahar tsabtace tayoyin Laser sosai a masana'antar taya a Turai da Amurka.Kodayake farashin saka hannun jari na farko yana da ɗan girma, fa'idodin adana lokacin jiran aiki, guje wa lalatawar ƙira, amincin aiki da adana albarkatun ƙasa za a iya dawo dasu cikin sauri.Dangane da gwajin tsaftacewa da na'urar tsaftacewa ta Laser ta gudanar a kan layin samar da kamfanin taya, yana ɗaukar sa'o'i 2 kawai don tsaftace saitin manyan motocin taya na kan layi.Idan aka kwatanta da hanyoyin tsaftacewa na al'ada, amfanin tattalin arziki a bayyane yake.

Fim ɗin fim ɗin anti-stick na roba akan ƙirar masana'antar abinci yana buƙatar maye gurbin akai-akai don tabbatar da tsabta.Laser tsaftacewa ba tare da sinadaran reagents shima ya dace da wannan aikace-aikacen.

2. Tsaftace makamai da kayan aiki:

Ana amfani da fasahar tsabtace Laser sosai a cikin kula da makami.Tsarin tsaftacewa na Laser zai iya cire tsatsa da ƙazanta da sauri da sauri, kuma zai iya zaɓar sassan tsaftacewa don gane aikin tsaftacewa ta atomatik.Yin amfani da tsaftacewa na laser, ba wai kawai tsaftacewa ya fi girma fiye da tsarin tsabtace sinadarai ba, amma kuma kusan babu lahani ga saman abu.Ta hanyar saita sigogi daban-daban, za a iya samar da fim ɗin kariya mai yawa oxide ko narkakken ƙarfe a saman abin ƙarfe don inganta ƙarfin saman da juriyar lalata.Abubuwan sharar da Laser ya cire ba ya gurɓata muhalli, kuma ana iya sarrafa shi daga nesa, yadda ya kamata ya rage lalacewar lafiya ga ma'aikacin.

3.Cire tsohon fentin jirgin sama:

An dade ana amfani da tsarin tsaftace Laser a masana'antar sufurin jiragen sama a Turai.Dole ne a sake fentin saman jirgin bayan wani ɗan lokaci, amma dole ne a cire tsohon fenti gaba ɗaya kafin zanen.Hanyar kawar da fenti na gargajiya na iya haifar da lahani ga ƙarfen jirgin cikin sauƙi kuma ya kawo ɓoyayyiyar haɗari ga jirgin sama mai aminci.Idan ana amfani da tsarin tsaftacewa da yawa na Laser, fenti a saman A320 Airbus za a iya cire shi gaba ɗaya cikin kwanaki biyu ba tare da lalata saman ƙarfe ba.

4.Tsaftacewa a cikin masana'antar lantarki

Masana'antar lantarki tana amfani da lasers don cire oxides: Masana'antar lantarki tana buƙatar ƙazanta daidaitattun daidaito, kuma lasers sun dace musamman don cire oxide.Kafin a siyar da allon kewayawa, fitilun abubuwan dole ne a lalata su sosai don tabbatar da mafi kyawun haɗin wutar lantarki, kuma ba dole ba ne a lalata fil ɗin yayin aiwatar da lalatawar.Tsabtace Laser na iya saduwa da buƙatun amfani, kuma ingancin yana da girma sosai, kawai ɗigon Laser ɗin yana haskakawa.

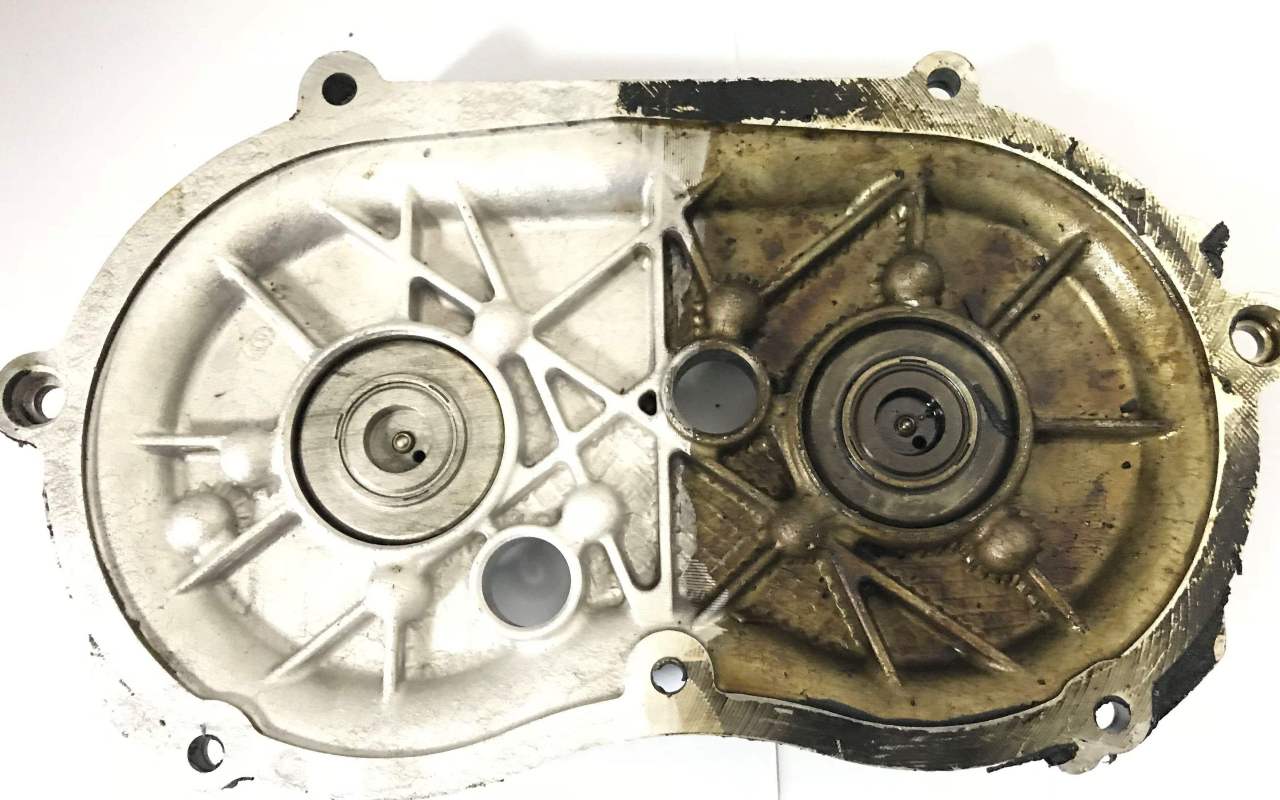

5.Madaidaicin tsaftacewa mai tsabta a cikin masana'antar injuna daidai:

Madaidaicin masana'antar injuna sau da yawa yana buƙatar cire esters da mai na ma'adinai da ake amfani da su don lubrication da juriya na lalata akan sassa, yawanci ta hanyoyin sinadarai, kuma tsabtace sinadarai galibi yana da ragowar.Ƙwararren Laser na iya cire esters gaba ɗaya da man ma'adinai ba tare da lalata saman ɓangaren ba.Ana kammala kawar da gurɓataccen gurɓataccen iska ta hanyar girgizar ƙasa, kuma fashewar iskar gas na bakin bakin bakin Layer oxide a saman sassan sassan ya haifar da girgizar girgiza, wanda ke kaiwa ga kawar da datti maimakon hulɗar injina.An cire kayan da kyau sosai kuma ana amfani dashi don tsaftace sassan injiniyoyi a cikin masana'antar sararin samaniya.Hakanan ana iya amfani da tsaftacewar Laser don cire mai da ester a cikin sarrafa sassan injina.

Lokacin aikawa: Janairu-11-2022