Hanyar walda Laser: Laser walda injiyana amfani da katako mai ƙarfi na Laser don haskaka saman saman ƙarfe, a cikin gida yana dumama kayan a cikin ƙaramin yanki, kuma yana narkar da kayan don samar da takamaiman narkakken tafkin don cimma manufar walda.

Fasalolin na'urar walda ta Laser:

Yana da wani sabon nau'i na walda hanya, yafi ga waldi na lafiya sassa, wanda zai iya kammala tabo waldi, butt waldi, dinki waldi, sealing waldi, da dai sauransu, tare da high al'amari rabo, kananan weld nisa, kananan zafi shafi yankin, kananan. nakasawa, da kuma saurin walda.Fast, lebur da kyau waldi kabu, babu bukatar magani ko kawai sauki magani bayan waldi, high waldi kabu ingancin, babu porosity, m iko, kananan taro tabo, high sakawa daidaito, sauki don kammala aiki da kai.Yana amfani da bugun jini na Laser mai ƙarfi don ɗora ɗanɗano kayan a cikin ƙaramin yanki.Ƙarfin wutar lantarki na Laser yana bazuwa cikin kayan ta hanyar tafiyar da zafi, yana narkar da kayan don samar da wani takamaiman tafki na narkakkar, sa'an nan kuma ya narkar da kayan biyu tare da juna.

Nau'in na'urorin walda na Laser:

An kasu kashi biyu-①Na'urar waldawa Laser kayan adoAn fi amfani da shi don gyaran ramuka, blisters na walda, da gyaran walda na kayan ado na zinariya da na azurfa.

Zabi na kayan ado Laser waldi inji:

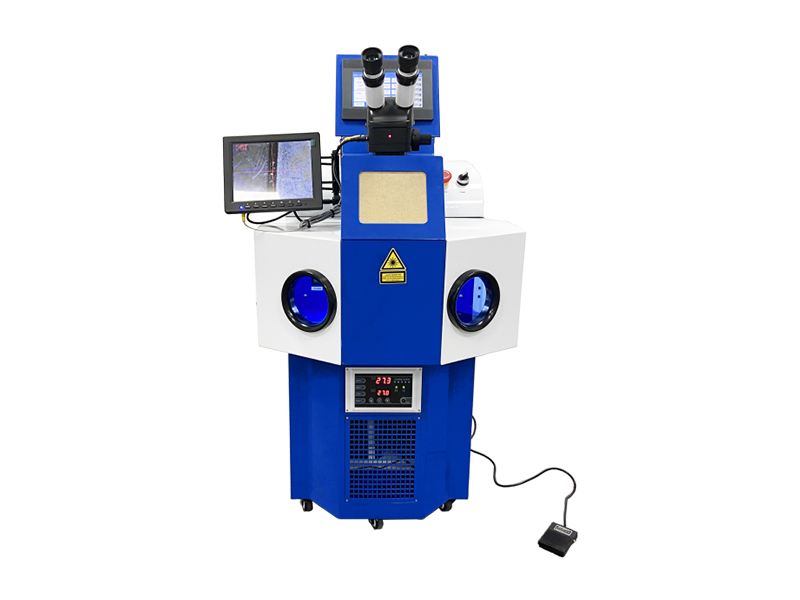

1)AKWAI LASER WELDING MASHIN-Raba Chiller Ruwa

Laser waldi yana sake daidaita tsarin kwayoyin kamanni ko nau'ikan karafa a walda, yana yin gami guda biyu na gama gari daya.Yin amfani da na'ura mai kula da microscope na musamman ko tsarin kulawa na CCD da na'urar tacewa mai sauri na lantarki na iya kare mai aiki da kyau, tasirin walda yana da kwanciyar hankali kuma abin dogara, kuma ƙarancin gazawar yana da ƙasa.

2)KAYAN ADOLASER welding Machine-Ingina Chiller Ruwa

Don cika porosity, sake kunna platinum ko saitunan tine na gwal, gyaran saitunan bezel, gyara / girman zobe da mundaye ba tare da cire duwatsu ba da gyara kurakuran masana'anta.Tsarin lura shine tsarin duba microscope ko tsarin kulawa da lura da CCD.

3)AKWAI LASER WELDING MASHIN- Desktop Model

Samfuri ne na musamman don walƙiya Laser kayan ado, galibi ana amfani dashi don ramuka da tabo walda a cikin kayan ado na zinariya da azurfa.Laser walda inji yana daya daga cikin muhimman al'amurran da aikace-aikace na Laser kayan sarrafa fasahar.Ana siffanta shi da saurin matsawa na ɗigon ja, nunin CCD na tsarin lura, da na'ura mai ƙima ta zaɓi.

An yafi amfani da Laser walda gyara na manya da kanana molds.Ana amfani da bugun jini mai ƙarfi na Laser don dumama kayan cikin gida a cikin ƙaramin yanki.Ƙarfin wutar lantarki na Laser yana bazuwa cikin kayan ciki ta hanyar tafiyar da zafi, kuma kayan biyu suna narke da haɗuwa tare.

Zabi na mold Laser waldi inji:

1)Fiber Laser Welding Machine-Nau'in Hannu

Yana ɗaukar sabon ƙarni na Laser fiber kuma an sanye shi da manyan kawunan walda na Laser, mafi sassauƙa don abubuwa daban-daban.Sauƙaƙan aiki, kyakkyawan suturar walda, saurin walda da sauri kuma babu kayan amfani.

2)3-AxisLaser Weld Machine- Nau'in atomatik

Yana iya kammala atomatik tabo waldi, amma waldi tari waldi da hatimi waldi ta sanye take da uku gatari ko hudu ball dunƙule tebur da shigo da servo iko tsarin, da nufin a hadaddun jirgin sama madaidaiciya line.

3)Mold Laser Welding Machine- Nau'in Manual

Yafi don walda na bakin ciki-banga kayan da madaidaicin sassa.Yana iya gane tabo waldi, butt waldi, dinki waldi, shãfe haske waldi, da dai sauransu, tare da babban al'amari rabo, kananan weld nisa, kananan zafi-shafi yankin da kuma kananan nakasawa.

4)Cantilever Laser Welding Machine- Tare da Lazy Arm

Tare da hannun cantilever, wanda ya fi dacewa da babban walƙiya.Ana iya juya zuwa duk kwatance da kusurwoyi, X, Y, Z axis m da yardar kaina, sosai warware walda wuya, inganta aiki yadda ya dace.

Abin da ke sama shine taƙaitaccen gabatarwar na'urar waldawa ta Laser.Idan kuna son ƙarin sani, zaku iya koya daga hanyoyin haɗin kan kowane samfur.

Lokacin aikawa: Mayu-05-2023