Gabatarwa zuwaLaser CleaningTsarin Masana'antar tsaftacewa ta gargajiya tana da hanyoyin tsaftacewa iri-iri, galibi suna amfani da sinadarai da hanyoyin injiniya don tsaftacewa.A cikin ƙa'idodin kare muhalli na yau da kullun da kuma ƙara wayewar mutane game da kariyar muhalli da aminci, nau'ikan sinadarai da za a iya amfani da su wajen tsabtace masana'antu za su yi ƙasa da ƙasa.Yadda za a nemo hanyar tsaftacewa mai tsabta da mara lalacewa matsala ce da ya kamata mu yi la'akari.Laser tsaftacewa yana da halaye na babu nika, ba lamba, babu thermal sakamako, kuma ya dace da abubuwa na daban-daban kayan, kuma an dauke su zama wani tasiri bayani.

Laser tsaftacewa injisabon ƙarni ne na samfuran fasaha na fasaha don tsabtace ƙasa.Sauƙi don shigarwa, aiki da sarrafa kansa.Aiki mai sauƙi, kunna wutar lantarki kuma kunna kayan aiki, zaku iya tsaftacewa ba tare da reagents na sinadarai ba, matsakaici, da ruwa.Yana da fa'idodin daidaitawa da hannu da hannu, tsaftacewa tare da filaye masu lanƙwasa, da tsaftace tsaftar ƙasa.Tabo, datti, tsatsa, sutura, plating, fenti, da sauransu.

1. Features

1) tsaftacewa mara lamba, babu lalacewa ga matrix sassan.

2) Madaidaicin tsaftacewa, wanda zai iya cimma zaɓin tsaftacewa na madaidaicin wuri da madaidaicin girman.

3) Babu maganin tsabtace sinadarai, babu kayan amfani, amintattu da abokantaka na muhalli

4) Aiki yana da sauƙi, ana iya kunna shi, kuma ana iya riƙe shi da hannu ko haɗin gwiwa tare da manipulator don gane tsaftacewa ta atomatik.

5) Tsarin tsaftacewa yana da girma sosai, yana adana lokaci.

6) The Laser tsaftacewa tsarin ne barga da kuma bukatar kusan babu goyon baya.

2.Aikace-aikace

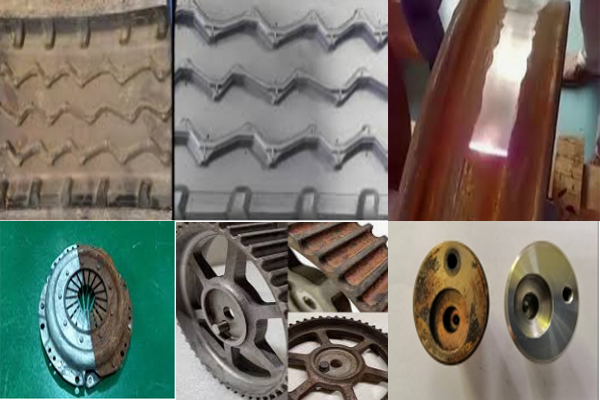

Ana amfani da tsaftacewar Laser sosai a masana'antu daban-daban, kamar: ginin jirgi, sassan mota, gyare-gyaren roba, kayan aikin injin, ƙirar taya, dogo, masana'antar kare muhalli da sauran masana'antu.

A fagen aikace-aikacen masana'antu, abubuwan tsaftacewa na Laser sun kasu kashi biyu: abubuwa masu tsabta da tsaftacewa.Abubuwan da ake amfani da su sun haɗa da yadudduka na gurɓataccen ƙasa na ƙarfe daban-daban, wafers na semiconductor, yumbu, kayan maganadisu, robobi da abubuwan gani.Abubuwan tsaftacewa sun haɗa da farfajiya A cikin filin masana'antu, ana amfani dashi sosai a cire tsatsa, cirewar fenti, cirewar mai, cirewar fim / cirewar iskar shaka, da guduro, manne, ƙura da kuma cire slag.

3.Cleaning aikace-aikace naLaser tsaftacewa injia cikin masana'antar kera motoci

Hanyoyin tsaftacewa na al'ada suna ɗaukar lokaci, ba za a iya sarrafa su ta atomatik ba, kuma sau da yawa suna da tasiri mai tasiri akan yanayi.The azumi, sarrafa kansa yanayi na Laser tsaftacewa damar domin sosai tsaftacewa na surface sharan gona, sakamakon da karfi, banza- da micro-crack-free welds da shaidu.Bugu da kari, Laser tsaftacewa ne m da kuma tsari ne muhimmanci sauri fiye da sauran hanyoyin, abũbuwan amfãni da cewa an gane da mota masana'antu.A cikin masana'antu, don kare karfe ko wasu kayan aiki, ana fentin saman gabaɗaya don hana tsatsa, oxidation, da lalata.Lokacin da fentin fenti ya ɗan cire ko kuma ana buƙatar fenti don wasu dalilai, asalin fentin ɗin yana buƙatar tsaftacewa gaba ɗaya.

Zaɓar fenti yana ɗaya daga cikin aikace-aikacen da yawa na tsaftacewa na Laser, sau da yawa saman yanayin yanayin abin hawa yana buƙatar cirewa sosai kafin a iya shafa sabon fenti.Tun da kayan aikin jiki da na sinadarai na saman fenti sun bambanta da na farko, ana iya saita iko da mita na laser don cire kawai saman saman fenti.

Laser tsaftacewa injiyana da tasiri sosai a cikin yanayin da dole ne a cire walda mai mahimmanci akan sassa na tsarin fenti don dubawa.Lasers na iya cire sutura ba tare da buƙatar hannun hannu ko kayan aikin wuta ba, abrasives ko sinadarai waɗanda zasu iya ɓoye wuraren matsala kuma su haifar da ƙarin lalacewa a saman.Wuhan Ruifeng Optoelectronics Laser yana ɗaya daga cikin rukunin farko na kamfanonin kayan aikin Laser.Tare da fiye da shekaru goma na R & D da ƙwarewar samarwa, yana jagorantar masana'antu dangane da fasaha da haɗin kai.Tun lokacin da aka kafa, kamfanin ya ko da yaushe biya da hankali ga bincike da kuma ci gaban Laser fasahar da ci gaban bukatun abokan ciniki, kuma ya jajirce wajen samar da cikakken kayan aiki mafita ga kowane sha'anin.

Lokacin aikawa: Juni-28-2023