Laser walda wata dabara ce ta walƙiya da ake amfani da ita don haɗa guda da yawa na karfe ta hanyar amfani da Laser katako.The Laser walda tsarin samar da wani mayar da hankali zafi tushen, kyale ga kunkuntar, zurfin welds da high waldi rates.Ana amfani da wannan tsari akai-akai a aikace-aikacen walda mai girma, kamar a cikin Masana'antar Motoci.

Laser walda yana hanzarta aiwatar da maye gurbin jabun sassa da sassa masu hatimi.Ana amfani da waldawar Laser don maye gurbin saɓanin tabo mai hankali tare da ci gaba da walƙiya na Laser, wanda zai iya rage fāɗin zoba da wasu sassan ƙarfafawa, kuma yana iya damfara ƙarar tsarin jiki da kansa.A sakamakon haka, za a iya rage nauyin jikin abin hawa da 56kg.Aikace-aikacen walda na Laser ya sami raguwar nauyi da raguwar fitarwa, wanda ya dace da buƙatun kare muhalli a zamanin yau.

Ana amfani da walda na Laser don yin walda na faranti marasa kauri, kuma fa'idodin sun fi mahimmanci.Wannan fasaha tana canza tsarin masana'anta na gargajiya - tambarin farko zuwa sassa, sannan tabo walda zuwa gabaɗaya: da farko walda sassa da yawa masu kauri daban-daban zuwa gabaɗaya, sannan ta buga da kafawa, rage adadin sassa da amfani da ƙarin kayan.Ma'ana, tsari da aiki suna inganta sosai.

Sau da yawa ana amfani da hanyoyin walda laser daban-daban don walda sassan jiki daban-daban.Wadannan sune jerin hanyoyin walda na Laser da yawa da aka saba amfani da su a masana'antar kera motoci.

(1) Laser brazing

Ana amfani da brazing Laser mafi yawa don haɗin saman murfin da bangon gefe, murfi na akwati, da dai sauransu. Volkswagen, Audi, Peugeot, Ford, Fiat, Cadillac, da dai sauransu duk suna amfani da wannan hanyar walda.

(2) Laser kai-fusion waldi

Laser kai-fusion waldi nasa ne mai zurfi shigar azzakari cikin farji waldi, wanda aka yafi amfani ga rufin da gefe bangarori, mota kofofin, da dai sauransu A halin yanzu, da yawa iri motoci na Volkswagen, Ford, GM, Volvo da sauran masana'antun amfani Laser kai Fusion waldi.

(3) Laser m waldi

Laser m waldi yana amfani da robot + galvanometer, m katako sakawa + waldi, da kuma fa'idar ta'allaka ne a ƙwarai ragewa da sakawa lokaci da mafi girma yadda ya dace idan aka kwatanta da gargajiya Laser aiki.

Hakanan za'a iya amfani da waldawar Laser akan sigari, masu ɗaukar bawul, gacets na silinda, injectors mai, filogi, gears, shingen gefe, mashinan tuƙi, radiators, clutches, bututun injin shayewa, axles na caji, da gyare-gyaren jakar iska da gyaran mota da ta lalace. sassa.

Waldawar Laser yana da fa'idodi da fa'idodi masu yawa akan hanyoyin walda na gargajiya kuma yana iya rage farashi sosai yayin haɓaka haɓakar samarwa da inganci.

walda Laser yana da halaye masu zuwa:

① kunkuntar dumama kewayon (mai da hankali).

②Yankin aikin da matsayi ana iya sarrafa shi daidai.

③Yankin da zafi ya shafa kadan ne.

④ The walda nakasawa ne karami, kuma ba bayan waldi gyara da ake bukata.

⑤ Ba lamba aiki, babu bukatar matsawa da workpiece da surface jiyya.

⑥ Yana iya gane walda na dissimilar kayan.

⑦ Gudun walda yana da sauri.

⑧Babu tasirin thermal, babu hayaniya da gurbacewa ga duniyar waje.

Na'urorin da aka ba da shawarar dacewa don walda mota sune kamar haka:

Laser walda Machine for Mold

Tare da ci gaban masana'antu, fasahar walƙiya ta Laser ana ci gaba da bincike da haɓakawa.A halin yanzu, a cikin inji waldi masana'antu, da rare Laser waldi inji ne saboda ta fice yi halaye da kuma nuna kyau tsari halaye a lokacin waldi tsari.Don haka ana iya amfani da shi sosai a fagage da yawa.

A mold a mold Laser waldi taka muhimmiyar rawa a cikin zamani masana'antu, da kuma ingancinsa kai tsaye kayyade ingancin samfurin.Haɓaka rayuwar sabis da daidaiton ƙirar ƙira da rage ƙirar ƙirar ƙira sune matsalolin fasaha waɗanda kamfanoni da yawa ke buƙatar gaggawa don warwarewa.Koyaya, yanayin gazawa kamar rugujewa, nakasawa, lalacewa, har ma da karyewa galibi suna faruwa yayin amfani da kyallen.Sabili da haka, fasahar gyaran walda ta Laser shima ya zama dole don gyara mold.

Na'urar walda ta Laser sabon nau'in hanyar walda ne, galibi don walda kayan sirara da madaidaicin sassa.Yana iya gane walda tabo, walƙiyar gindi, walƙiya ɗinki, walƙiya mai ɗaukar nauyi, da sauransu, tare da babban al'amari, ƙaramin girman walda, da yankin da zafi ya shafa.Ƙananan, ƙananan nakasawa, saurin walƙiya mai sauri, santsi da kyawawan suturar walda, babu buƙatar ko aiki mai sauƙi bayan waldawa, babban ingancin walda, babu ramukan iska, daidaitaccen iko, ƙaramin tabo mai da hankali, babban matsayi daidai, da sauƙin gane aiki da kai.

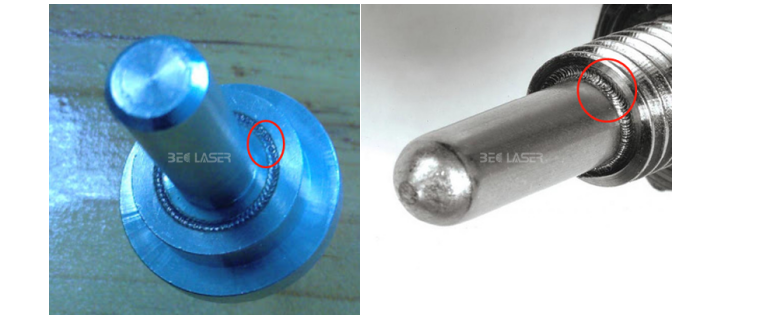

A hankula misali na aikace-aikace na Laser waldi a cikin mold masana'antu ne mold gyara Laser waldi inji.Wannan kayan aiki yana da sauƙi ga masu aiki don amfani da su, na iya ƙara yawan saurin gyare-gyaren walda, kuma tasirin gyare-gyare da daidaitattun suna kusa da kyau, wanda ke yin kayan aiki An yi amfani da shi sosai a fagen walƙiya.A gyara waldi zafi shafi yankin na wannan waldi inji ne kadan, kuma shi ba ya bukatar da za a mai tsanani a gaba, da kuma welded workpiece ba ya bayyana annealing sabon abu bayan aiki.Wannan fasahar gyaran walda ta Laser ba za a iya amfani da ita kawai don gyara lalacewa ba, har ma tana iya cimma daidaitattun walda na sassan jiki daban-daban.

Lokacin aikawa: Yuli-15-2021