Iyalin aikace-aikace nainjin walda laseryana ƙara girma, amma buƙatun kuma suna karuwa kuma suna karuwa.A lokacin aikin walda, ana buƙatar busa iskar gas don tabbatar da tasirin walda na samfurin yana da kyau.Don haka yadda za a yi amfani da busa iska daidai a cikin aiwatar da walƙiya Laser karfe?

A cikin waldawar Laser, iskar gas ɗin kariya tana shafar haɓakar walda, ingancin walda, shigar da walƙiya da faɗi, da sauransu.

Kyakkyawan sakamako na garkuwar gas akanna'ura waldi na Laser:

1. Daidai hurawa garkuwa gas iya yadda ya kamata kare weld pool don rage hadawan abu da iskar shaka, ko ma kauce wa kasancewa oxidized.

2. Yana iya yadda ya kamata rage spatter da aka samar a cikin aikin walda, da kuma taka rawa na kare mayar da hankali madubi ko m madubi.

3. Yana iya haɓaka yunifom shimfidawa na walda pool lokacin da ta dage, sabõda haka, weld ya zama uniform da kyau.

4. Iya yadda ya kamata rage weld pores.

Muddin an zaɓi nau'in gas, yawan iskar gas da hanyar busawa daidai, ana iya samun sakamako mai kyau.Koyaya, rashin amfani da iskar kariya na iya haifar da illa ga walda.

Mummunan illa na rashin amfani da iskar gas na kariya akan waldawar Laser:

1. Rashin isasshen iskar gas na kariya na iya haifar da rashin walda.

2. Zaɓi nau'in gas ɗin da ba daidai ba na iya haifar da tsagewa a cikin walda kuma yana iya haifar da raguwar kayan aikin walda.

3. Zabar da ba daidai ba iskar gas hura kwarara kudi na iya haifar da mafi tsanani hadawan abu da iskar shaka na walda (ko da kwarara kudi ne da yawa girma ko kuma karami), ko kuma yana iya sa walda pool karfe da za a tsanani damuwa da waje sojojin, haifar da walda don rugujewa ko samar da rashin daidaituwa.

4. Zaɓi hanyar busa iskar gas ɗin da ba ta dace ba zai sa walda ta kasa cimma ko ma ba ta da wani tasiri na kariya ko kuma yana da mummunan tasiri akan ƙirar walda.

Nau'in iskar gas mai kariya:

Yawanci amfaniwaldi na LaserGas masu kariya sun fi N2, Ar, He, kuma halayensu na zahiri da na sinadarai sun bambanta, don haka tasirin walda shima ya bambanta.

Argon

Ƙarfin ionization na Ar yana da ƙananan ƙananan, kuma matakin ionization a ƙarƙashin aikin laser yana da girma sosai, wanda ba shi da amfani don sarrafa samuwar girgije na plasma, kuma zai sami wani tasiri akan ingantaccen amfani da Laser.Duk da haka, aikin Ar yana da ƙasa sosai, kuma yana da wuya a yi maganin sunadarai tare da karafa na kowa.dauki, da kuma kudin Ar ba high.Bugu da ƙari, yawan Ar yana da girma, wanda ke taimakawa wajen nutsewa zuwa saman tafkin weld, wanda zai iya kare tafkin walda, don haka za'a iya amfani da shi azaman iskar kariya ta al'ada.

Nitrogen N2

Ƙarfin ionization na N2 yana da matsakaici, sama da na Ar, kuma ƙasa da na Shi.A karkashin aikin Laser, matakin ionization shine matsakaici, wanda zai iya rage samuwar girgijen plasma mafi kyau, ta haka yana haɓaka ingantaccen amfani da Laser.Nitrogen zai iya amsawa da sinadarai tare da aluminum gami da carbon karfe a wani zafin jiki don samar da nitrides, wanda zai ƙara brittleness na weld da kuma rage taurin, wanda zai yi wani mummunan tasiri a kan inji Properties na weld hadin gwiwa, don haka shi ne. Ba a ba da shawarar yin amfani da nitrogen ba.Aluminum gami da carbon karfe welds ana kiyaye su.Nitride da sinadarin sinadarai ke samarwa tsakanin nitrogen da bakin karfe na iya inganta ƙarfin haɗin gwiwar walda, wanda zai taimaka inganta injinan walda, don haka ana iya amfani da nitrogen azaman iskar gas mai kariya lokacin walda bakin karfe.

Helium Ya

Yana da mafi girman ƙarfin ionization, kuma digiri na ionization yana da ƙasa sosai a ƙarƙashin aikin laser, wanda zai iya sarrafa samuwar girgijen plasma sosai.Yana da kyau waldi garkuwa gas, amma farashin Ya yi yawa.Gabaɗaya, ba a amfani da wannan iskar a samfuran da ake samarwa da yawa.Gabaɗaya ana amfani da shi don binciken kimiyya ko samfuran da ke da ƙarin ƙima.

A halin yanzu akwai hanyoyi guda biyu na busa na al'ada don kariya ga iskar gas: busa gefen-shaft da busa coaxial

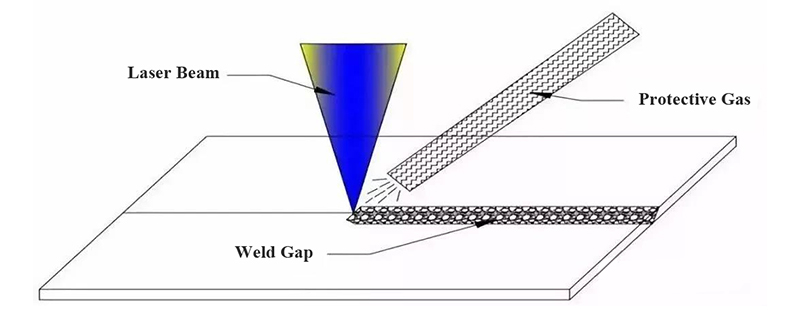

Hoto na 1: Busa gefen-shaft

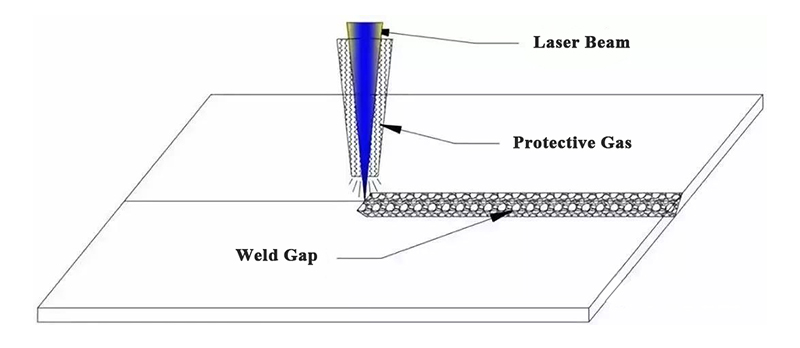

Hoto 2: Busa Coaxial

Yadda za a zabi hanyoyin busa guda biyu babban abin la'akari ne.Gabaɗaya, ana ba da shawarar yin amfani da hanyar iskar gas mai karewa ta gefe.

Hanyar zaɓin garkuwar iskar gas: yana da kyau a yi amfani da paraxial don welds madaidaiciya, da coaxial don zane mai rufaffiyar jirgin.

Da farko, yana buƙatar bayyana cewa abin da ake kira "oxidation" na weld shine kawai sunan kowa.A ka'ida, yana nufin cewa ana amsa walda ta hanyar sinadarai tare da abubuwa masu cutarwa a cikin iska, wanda ke haifar da lalacewar ingancin walda.Ya zama ruwan dare cewa karfen walda yana wani yanayin zafi.Yana amsa sinadarai tare da oxygen, nitrogen, hydrogen, da sauransu a cikin iska.

Hana walda daga zama “oxidized” shine ragewa ko hana irin waɗannan abubuwan da ke cutarwa daga haɗuwa da ƙarfen weld a yanayin zafi mai yawa, ba kawai narkakken ƙarfen tafkin ba, amma daga lokacin da ƙarfen walda ya narke har sai ƙarfen tafkin ya ƙarfafa. kuma zafinsa yana raguwa ƙasa da wani yanayin zafi a tsawon lokacin.

Misali, waldawar titanium na iya shan hydrogen da sauri lokacin da zafin jiki ya wuce 300 ° C, oxygen zai iya shiga cikin sauri lokacin da zafin jiki ya wuce 450 ° C, kuma nitrogen yana iya ɗaukar sauri lokacin da ya wuce 600 ° C, haka titanium. Alloy weld yana da ƙarfi kuma ana rage yawan zafin jiki zuwa 300 ° C Matakan da suka biyo baya suna buƙatar kariya sosai, in ba haka ba za su zama "oxidized".

Ba shi da wuya a fahimta daga bayanin da ke sama cewa iskar garkuwar da aka hura ba kawai tana buƙatar kare tafkin walda a kan kari ba, amma kuma yana buƙatar kare wurin da ya inganta wanda aka yi wa walda, don haka gabaɗaya gefen shaft ɗin gefe. wanda aka nuna a hoto 1 ana amfani dashi.Busa iskar kariya, saboda kewayon kariya na wannan hanyar ya fi na hanyar kariya ta coaxial a cikin hoto na 2, musamman wurin da walda ya inganta yana da mafi kyawun kariya.

Don aikace-aikacen injiniya, ba duk samfuran zasu iya amfani da gefen shaft na gefen busa iskar gas ba.Ga wasu takamaiman samfuran, ana iya amfani da iskar garkuwar coaxial kawai, wanda ke buƙatar aiwatar da shi daga tsarin samfurin da nau'in haɗin gwiwa.Zaɓin da aka yi niyya.

Zaɓin takamaiman hanyoyin busa iskar kariya:

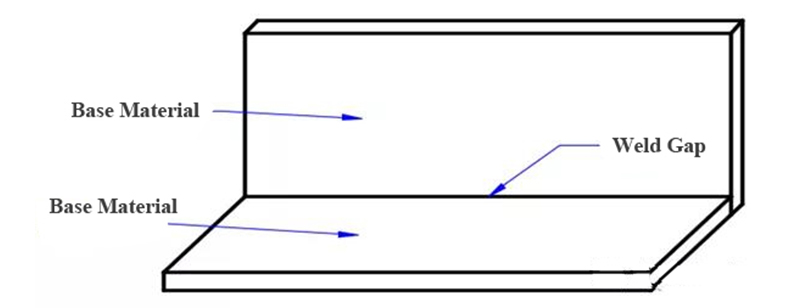

1. Madaidaicin Welds

Kamar yadda aka nuna a cikin Hoto na 3, siffar kabu na walda na samfurin shine madaidaiciyar layi, kuma nau'in haɗin gwiwa shine haɗin gindi, haɗin gwiwa, haɗin gwiwa na kusurwa na ciki ko haɗin haɗin gwiwa.Zai fi kyau a busa iskar gas mai kariya a gefen shaft.

Hoto 3: Madaidaicin Welds

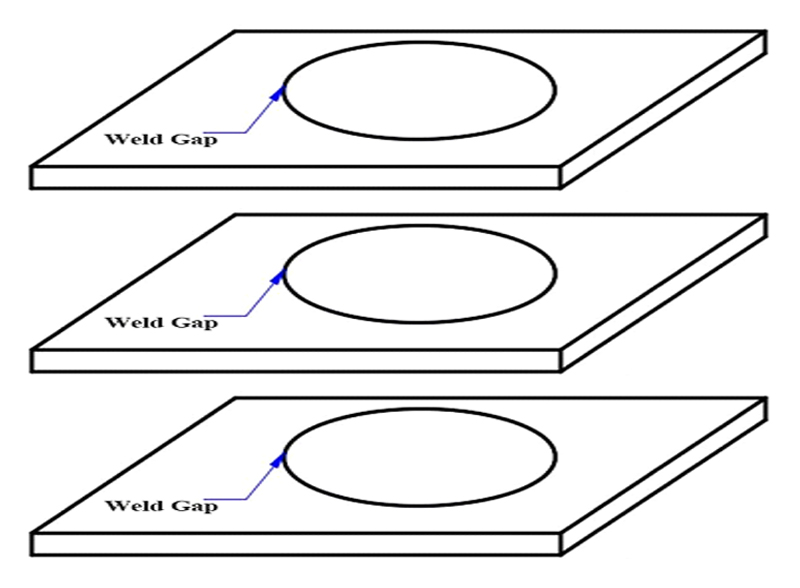

2. Lebur rufaffiyar hoto welds

Kamar yadda aka nuna a cikin hoto na 4, sifar walda na samfur ɗin rufaffiyar siffa ce kamar da'irar jirgin sama, polygon na jirgin sama, da layin fasinja da yawa.Zai fi kyau a yi amfani da hanyar iskar gas na coaxial da aka nuna a hoto na 2.

Hoto na 4: Lantarki Rufe Welds

Zaɓin garkuwar gas kai tsaye yana shafar inganci, inganci da farashin samar da walda.Duk da haka, saboda bambancin kayan walda, zaɓin gas ɗin walda shima yana da ɗan rikitarwa a ainihin aikin walda.Wajibi ne a yi la'akari sosai da kayan walda, hanyoyin waldawa, da matsayi na walda.Hakazalika tasirin walda da ake buƙata, ta hanyar gwajin walda kawai za'a iya zaɓin iskar walda mafi dacewa don cimma kyakkyawan sakamako na walda.

Lokacin aikawa: Mayu-08-2023