Laser walda injihanya ce mai inganci kuma madaidaiciyar walda wacce ke amfani da katako mai ƙarfi mai ƙarfi da ƙarfi azaman tushen zafi.Laser walda yana daya daga cikin muhimman al'amurran da aikace-aikace na Laser kayan sarrafa fasahar.A cikin 1970s, an fi amfani da shi don walda kayan katangar bango da walƙiya mara sauri.Tsarin walda yana da nau'in gudanarwa na thermal, wato, saman kayan aikin yana dumama ta hanyar radiation laser, kuma yanayin zafi yana yaduwa zuwa ciki ta hanyar tafiyar da zafi.Ta hanyar sarrafa faɗin, kuzari, ƙarfin kololuwa da maimaitawa na bugun bugun laser da sauran sigogi don narke aikin aikin da samar da takamaiman narkakken tafkin.Saboda fa'idodinsa na musamman, an yi amfani da shi cikin nasara a daidaitaccen walda na ƙananan sassa da ƙananan sassa.

一, Halayen walda

Yana da walƙiya fusion, wanda ke amfani da katako na Laser azaman tushen makamashi don tasiri akan haɗin gwiwar walda.

Za a iya jagorantar katakon Laser ta hanyar lebur na gani, kamar madubi, sa'an nan kuma a hange shi a kan kabu na walda ta hanyar wani abu mai haske ko madubi.

Waldawar Laser ba walƙiya ce ta hanyar sadarwa ba, ba a buƙatar matsa lamba yayin aiki, amma ana buƙatar iskar gas mai ƙarfi don hana iskar oxygen da narkakken tafkin, kuma ana amfani da ƙarfe na ƙarfe lokaci-lokaci.

Ana iya haɗa waldawar Laser tare da walƙiya na MIG don samar da walƙiyar Laser MIG don cimma babban walƙar shigar ciki, kuma an rage shigar da zafi sosai idan aka kwatanta da walƙar MIG.

二, Aiki manufa na mold waldi inji

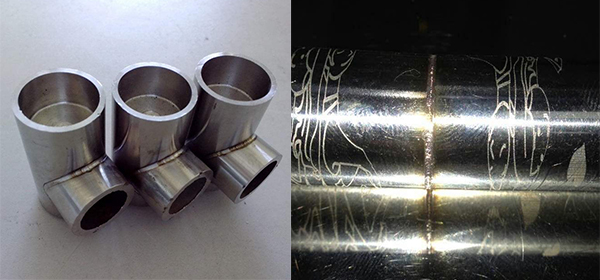

The mold Laser waldi inji ne kuma reshe nana'ura waldi na Laser, don haka ka'idar aiki ita ce yin amfani da ƙwanƙwasa laser mai ƙarfi don zafi da kayan cikin gida a cikin ƙaramin yanki.Ƙarfin wutar lantarki na Laser yana yaduwa a cikin kayan ta hanyar zafin zafi, kuma kayan ya narke kuma ya kafa.takamaiman narke tafkin.Yana da wani sabon irin waldi hanya, yafi ga waldi na bakin ciki-banga kayan da daidaici sassa, da kuma iya gane tabo waldi, butt waldi, dinki waldi, sealing waldi, da dai sauransu Small nakasawa, azumi waldi gudun, santsi da kyau waldi. kabu, babu bukata ko sauki magani bayan waldi, high waldi ingancin kabu, babu pores, daidai iko, kananan mayar da hankali tabo, high sakawa daidaito, da kuma sauki aiki da kai.An ƙaddamar da injunan walƙiya mai ƙarfi na Laser, kuma ana iya samun nau'ikan nau'ikan injin walda na Laser da gyare-gyare don abubuwa masu kauri.

Misali:

三, The halaye na mold Laser waldi

Na'urar waldawa ta gyaggyarawa tana ɗaukar babban allo na LCD na Sinanci, wanda ke sauƙaƙa wa mai aiki don koyo da aiki.Har ila yau, kayan aiki suna ɗaukar aikin tsara shirye-shiryen rubutu don gane aikin multimode, wanda ya dace da gyaran gyare-gyare na yawancin kayan.Ba wai kawai yankin da ke fama da zafi yana da ƙananan ba, ƙwayar oxidation yana da ƙananan, amma kuma ba za a sami blisters, pores da sauran abubuwan mamaki ba.Bayan gyaran gyare-gyaren, sakamakon gyare-gyaren shine don cimma rashin daidaituwa a haɗin gwiwa, kuma ba zai haifar da nakasawa ba.

四, Fasahar daidaitawa da sarrafawa

1. Moldna'ura waldi na Laseryakamata ayi amfani da microscope 10X ko 15X don saka idanu akan aikin.

2. Ƙarfin wutar lantarki na na'ura mai walƙiya laser na iya ɗaukar aikin daidaitawa na waveform, wanda ya dace da walƙiya na kayan daban-daban.Kamar: mutu karfe, bakin karfe, beryllium jan karfe, aluminum, da dai sauransu.

3. Ana iya amfani da tsarin CCD (tsarin kyamara) don saka idanu, aikin shine: ban da ma'aikacin da ke kallo daga microscope, masu aiki ba zasu iya kallon tsarin walda gaba ɗaya ta hanyar allon nuni na tsarin kyamara, wannan na'urar shine. da amfani ga rashin aiki Horon fasaha na ma'aikata da nunin nuni sun taka muhimmiyar rawa wajen inganta fasahar waldawar laser.

4. Yana iya narke walda wayoyi na diamita daban-daban, daga 0.2 zuwa 0.8 a diamita.

5. The mold Laser waldi inji dole ne a kiyaye ta argon gas, da kuma shirin ya kamata a saita zuwa emit argon gas farko sa'an nan Laser don hana hadawan abu da iskar shaka na farko pulsed Laser a lokacin ci gaba da aiki.

6. Lokacin da gyaggyarawa ke walda laser, abin da ya fi faruwa shine akwai alamun cizo a kusa da sashin walda.Wajibi ne a yi amfani da hanyar bugun iska na Laser don rufe canje-canjen da ka iya haifar da alamun cizo don hana faruwar alamun cizo.Ya wadatar cewa wurin haske ya wuce gefen matsayin walda da 0.1mm.

Lokacin aikawa: Juni-12-2023